Tailor-made Tank Solutions

Hygienic, Certified & Durable

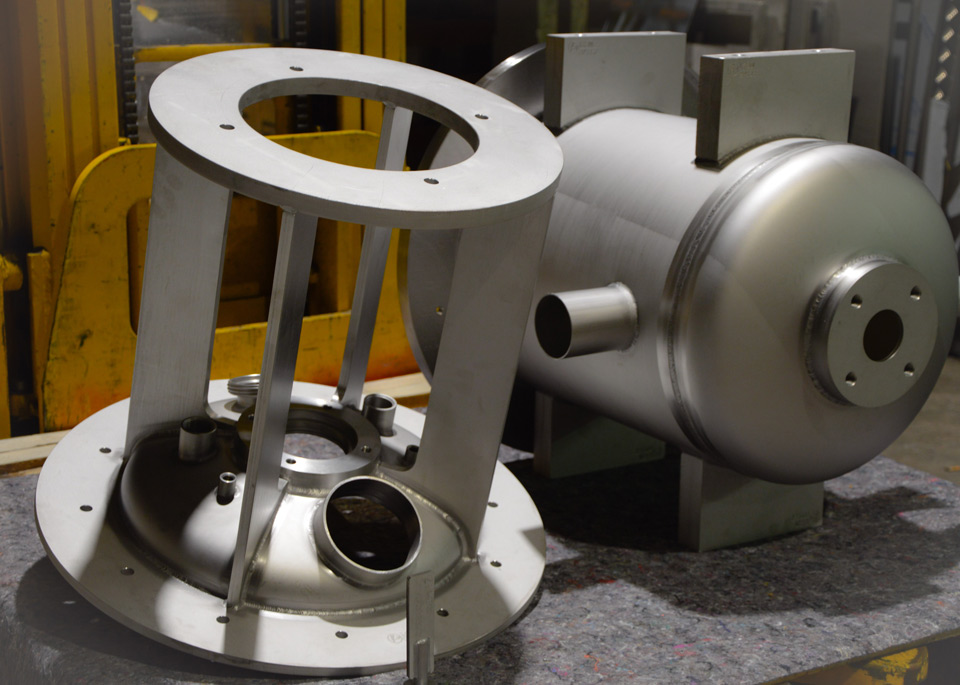

Stainless steel tanks are the heart of many processes in the food, pharmaceutical, and chemical industries. Wherever purity, safety, and longevity are essential, our custom-made stainless steel tanks provide a reliable foundation. Weiss Apparatebau has specialized for years in planning and manufacturing exactly these kinds of solutions – flexible, precise, and produced to the highest quality standards.

High Requirements for Hygiene and Process Safety

In sensitive industrial sectors, even the slightest deviation in tank design can have serious consequences – from contamination and production downtime to legal risks.

Custom Stainless Steel Tanks –

Made in Germany

Weiss Apparatebau develops stainless steel tanks precisely tailored to your processes. Whether pressure vessels, mixing tanks, storage tanks or special designs – we realize your project with expertise, precision, and passion.

What Makes Our Stainless Steel Tanks Stand Out

Certified Safety

For Your Processes

Rely on proven quality – for all safety-relevant applications where precision, hygiene, and documentation are top priorities. Our stainless steel tanks are manufactured under the strictest conditions and regularly inspected. This ensures not only legal compliance but also maximum safety and transparency – in black and white.

Rely on our experience to implement your processes safely, efficiently, and hygienically:

Versatile Stainless Steel Tank Solutions

A selection of our proven product types for your specific requirements

| Type | Volume | Special Features |

|---|---|---|

| Mixing Tanks | As requested | With magnetic stirrer, double jacket, CIP |

| Pressure Vessels | As requested | Tested, CE-certified, documented |

| Storage Tanks | As requested | Hygienically welded, with cleaning connections |

| Custom Constructions | Custom-made | Tanks with special geometries |

Insights into Stainless Steel Tanks

From certified manufacturing – directly from the expert

For applications with high hygiene requirements, stainless steels of grade 1.4404 (316L) or 1.4571 (316Ti) are primarily used. These materials are resistant to aggressive cleaning agents and offer excellent corrosion resistance.

Depending on the medium or temperature range, duplex or special alloys such as Hastelloy may also be appropriate. We will gladly advise you on the optimal material selection for your specific application.

Certified manufacturing means that all production processes are documented, verifiable, and follow defined quality standards. This includes CE certifications for pressure equipment or approved welding processes according to DIN EN ISO 3834-3.

For you as a customer, this means: maximum product safety, traceable material origin through re-stamping authorization, and legal compliance during official inspections.

Stainless steel tanks used in sensitive areas such as the food, pharmaceutical, or chemical industries must meet strict requirements. This includes compliance with standards such as DIN EN ISO 3834-3 and AD 2000-Merkblatt HP0 for pressure-bearing components.

A hygienic design also means: dead space-free construction, easy-to-clean surfaces (Ra ≤ 0.8 μm), and the integration of CIP/SIP systems. Only in this way can contamination-free operation in continuous use be ensured.

An experienced manufacturer not only brings the necessary technical know-how but also understands industry-specific requirements. Especially for custom constructions or complex systems, close coordination with a qualified partner is crucial.

Weiss Apparatebau offers you: personal consultation, in-house production, comprehensive documentation – and thus a solution you can rely on.