Sterile Technology for the Highest Hygiene Standards

Essential in Sensitive Industries

Whether in food production, pharmaceuticals, or biotech – wherever absolute cleanliness and sterile processes are critical, sterile technology plays a key role. Our solutions stand for uncompromising quality, durability, and safety – custom-made to meet the highest requirements or available as standardized components tailored to technical specifications.

Hygienic Challenges in Sensitive Sectors

In the food, pharmaceutical, or chemical industry, even the smallest contamination can result in major risks – affecting product quality, safety, and ultimately, your company’s reputation. Reliable sterile technology is therefore not an optional extra but an essential component of any well-functioning production process.

Wherever sterile conditions are required, there is no room for compromise.

Certifications in the Field of

Sterile Technology & Stainless Steel Processing

Unsere Zertifizierungen geben Ihnen die Sicherheit, dass alle Produkte nach höchsten Qualitäts- und Sicherheitsstandards gefertigt werden. Sie garantieren dokumentierte Lieferketten, verlässliche Partner und die Einhaltung gesetzlicher Anforderungen – ein entscheidender Vorteil für den Einsatz in sensiblen Bereichen wie Pharma, Lebensmittel oder Chemie.

Vertrauen Sie auf unsere Expertise, um Ihre Prozesse effizient und hygienisch zu gestalten.

Product Highlights

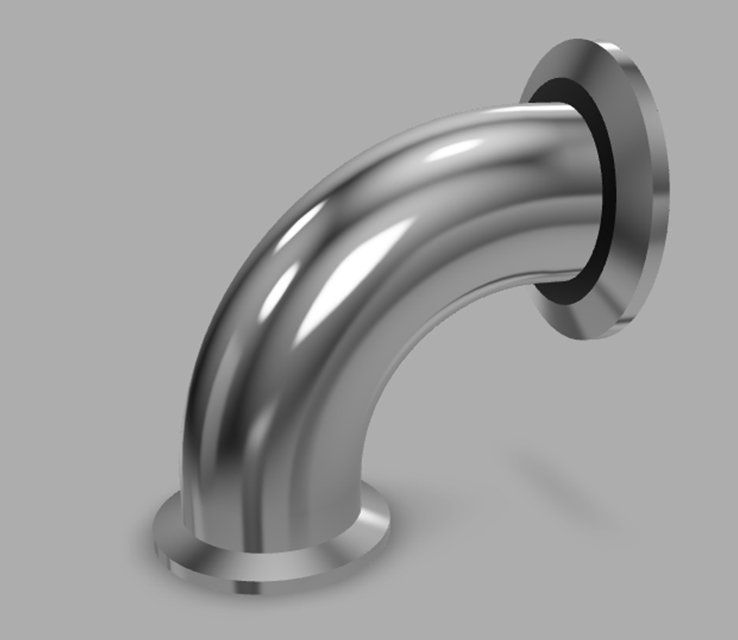

Stainless steel fittings for sterile applications – durable, precisely manufactured, and hygienically processed to meet the highest demands of modern industry.

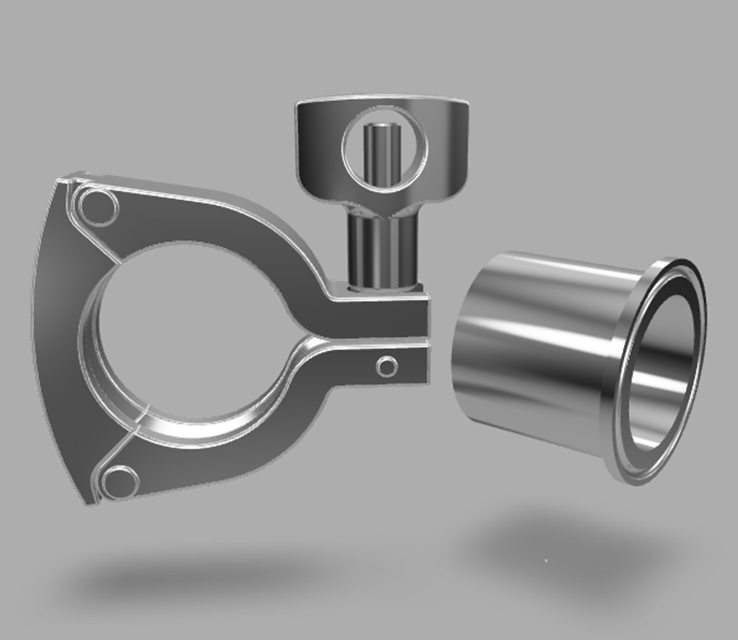

Tri-Clamp fittings in certified quality – for hygienic pipe connections and maximum safety in sensitive production environments.

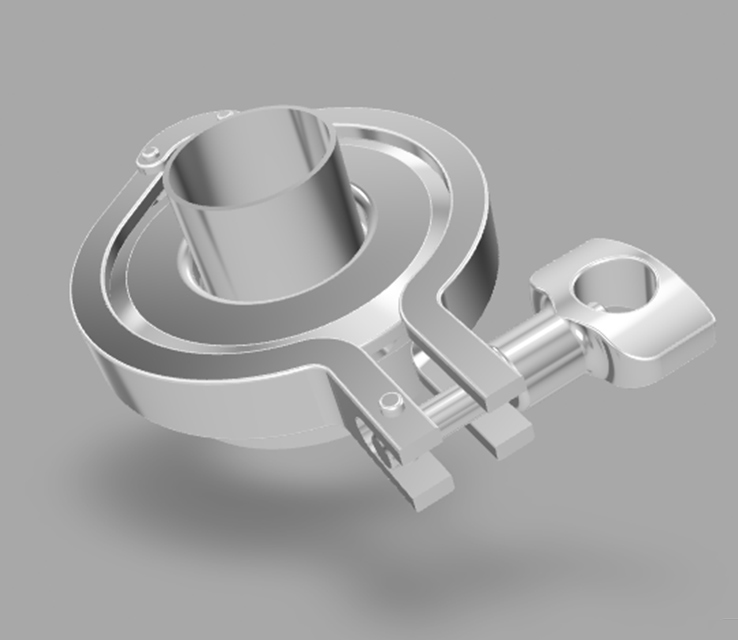

High-quality components for stainless steel tanks – flexibly combinable, robust, sterile, and compatible with all standard industrial applications.

Facts about Certified Sterile Technology

Answers to your most important questions – directly from the experts.

In sterile technology, austenitic stainless steels such as 1.4404 (316L) or 1.4435 have proven to be particularly effective. These alloys are corrosion-resistant, easy to clean, and meet the highest requirements for surface smoothness.

Depending on the industry and medium, Hastelloy may also be used – for example, when handling particularly aggressive substances or extreme temperatures.

Piping systems in hygiene-critical areas must be precisely planned, cleanly processed, and fully documented.

Only an experienced partner with certified processes can ensure safety, durability, and compliance – from material selection to final inspection.

A specialized provider like Weiss Apparatebau offers not only expertise but also takes full responsibility for your product.

Piping in hygienic applications must be free of dead space, easy to clean (CIP/SIP), and particle-free.

Smooth inner surfaces (e.g., Ra < 0.8 µm), inspected weld seams, and documented material traceability are essential.

Compliance with FDA, EHEDG, or GMP requirements also plays a central role depending on the industry.

Certified stainless steel pipelines are manufactured according to clearly defined quality standards – for example, according to AD 2000, DIN EN ISO 3834, or PED.

These standards ensure not only mechanical stability but above all hygiene, traceability, and production documentation.

For sensitive industries such as pharmaceuticals, biotechnology, or food, this is essential for product safety and audit compliance.