Solutions for Extreme Requirements

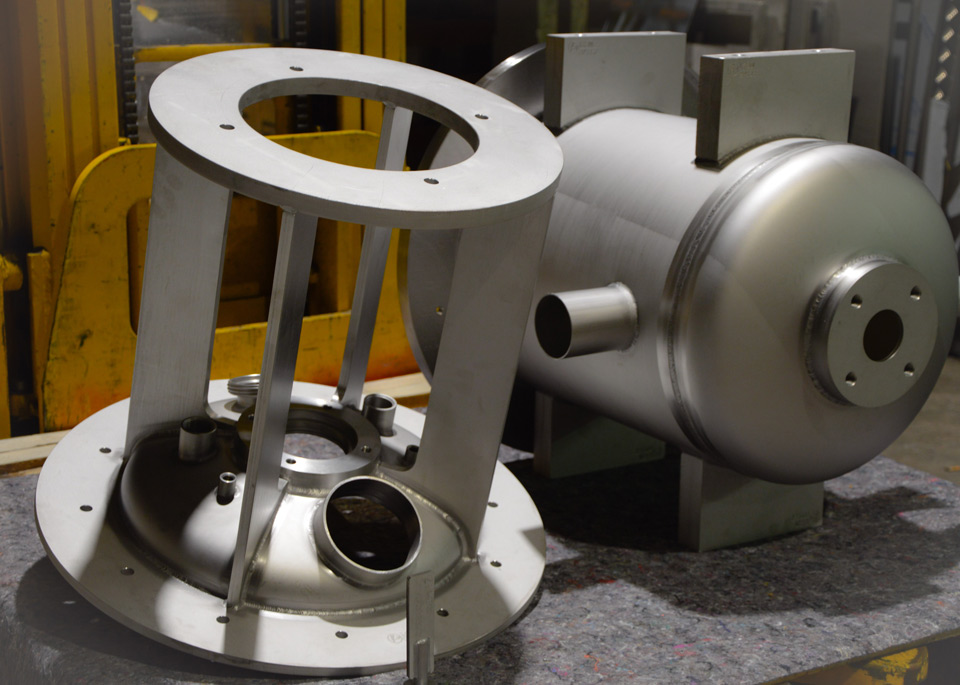

Hastelloy tanks are the first choice when conventional stainless steel reaches its limits. Whether dealing with aggressive media, extreme pH values or high temperatures – we manufacture custom-designed pressure and process vessels from Hastelloy C-22, C-276 and other special alloys. At Weiss, maximum corrosion resistance meets certified manufacturing quality – documented, tested and ready for demanding processes in the chemical, pharmaceutical and environmental industries.

What Sets Our Hastelloy Tanks Apart

Our Hastelloy tanks offer maximum corrosion resistance, certified welding technology, and custom engineering – ensuring safe processes in aggressive, sensitive, or hygienic environments.

Typical Applications for Hastelloy Tanks

Certified Safety for Demanding Processes

Rely on Proven Quality

Our Hastelloy tanks meet the highest safety standards – from planning through commissioning. You can rely on complete traceability, verified quality and documented production processes.

Our Certifications at a Glance:

Hastelloy Tanks for Highly Corrosive Processes

Extreme Conditions and Aggressive Media

Our Hastelloy tanks are specifically designed for applications where standard stainless steel is no longer sufficient. Whether high temperatures, highly corrosive media or hygienically sensitive processes – we deliver tailor-made Hastelloy tank solutions with certified quality and full documentation. Ideal for use in the chemical, pharmaceutical and process industries.

Frequently Asked Questions About Hastelloy Tanks

Hastelloy tanks are deployed wherever conventional stainless steel falls short, including:

– Chemical industry: Processing and storage of highly corrosive liquids

– Pharmaceutical industry: Sterile production environments with the highest hygiene standards

– Biotechnology: Media vessels for ultra-pure substances

– Research & development: Pilot plants under extreme conditions

– Surface technology & electroplating: Use in electrochemical processes

Compared to stainless steel, Hastelloy tanks offer significantly higher resistance to chemical corrosion, stress corrosion cracking, and oxidation.

They are ideal for extreme process conditions involving high temperatures and aggressive media.

In addition, Hastelloy tanks are easy to clean and therefore suitable for sterile processes – a major advantage in pharmaceutical and biotech applications.

The manufacturing of a Hastelloy tank is fully documented and follows certified procedures. From the initial needs assessment and individual planning to final production, we work closely with our customers.

Each component is precisely tailored to the respective process. State-of-the-art welding technology, material testing, and complete documentation ensure the highest quality and process reliability – ideal for GMP-compliant applications.

Hastelloy tanks are made from a high-alloy nickel-based material specifically developed for use in extremely corrosive environments.

They are used wherever stainless steel is no longer sufficient – for example, in the storage or processing of aggressive acids, alkalis, or solvents.

Typical areas of application include:

– The chemical industry

– Pharmaceutical production processes

– High-temperature applications in process engineering

At Weiss Apparatebau, all Hastelloy tanks are manufactured according to the highest quality standards. These include:

– AD 2000-Merkblatt HP0 for pressure vessel manufacturing

– DIN EN ISO 3834-3 for documented welding quality

– CE marking in accordance with PED for legally compliant use within the EU

– Authorized personnel for material re-stamping, ensuring complete traceability of materials

These certifications are essential, especially in safety-critical and audit-relevant industries.